As school funding dwindles, utility costs rise and operating budgets shrink, staff in K-12 schools become ever more resourceful in managing aging mechanical systems. With increasing pressures and workload, preventative maintenance is often low priority. Combined with outdated and inefficient HVAC equipment, schools find themselves with significantly higher energy costs. However, school staff can count on HVAC manufacturers to help overcome these obstacles with innovative, budget-friendly chiller designs that increase energy efficiency and simplify maintenance and service programs.

As school funding dwindles, utility costs rise and operating budgets shrink, staff in K-12 schools become ever more resourceful in managing aging mechanical systems. With increasing pressures and workload, preventative maintenance is often low priority. Combined with outdated and inefficient HVAC equipment, schools find themselves with significantly higher energy costs. However, school staff can count on HVAC manufacturers to help overcome these obstacles with innovative, budget-friendly chiller designs that increase energy efficiency and simplify maintenance and service programs.

Chillers are arguably a school building’s largest energy draw, but need not be costly and complex to be effective. New and widely accessible innovations in air-cooled scroll chiller designs — ranging from 30 to 240 tons — match performance requirements, budget constraints and maintenance requirements.

Cost of Ownership

Compared to typical screw chillers, air-cooled scroll chillers offer better part load efficiencies at a lower cost. They are also easier to service by in-house staff since the compressor technology is similar to residential equipment, which reduces dependency and costs for outside support.

In addition to these price advantages, some of the newest scroll chillers also produce unprecedented energy efficiencies. Sound pressure ratings as low as 60 dBA (decibel A-weighting) — without any optional acoustic treatment — means these quiet scroll chillers are optimal for noise sensitive environments. Combine this with a design that minimizes initial cost and these new scroll chiller systems provide K-12 schools with the lowest cost of ownership —from installation to replacement.

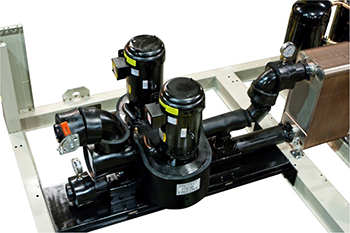

Particularly important when space is at a premium, scroll chillers offer design flexibility and a range of features. For example, pumps can be factory-installed inside the chiller instead of the mechanical room, eliminating the need to work with a design engineer onsite. A chiller-installed pump saves time and money during installation and preserves space inside the mechanical room.

Simpler mechanical layouts and easier installation also reduce contractor-related fees. For example, contractors can bring scroll chillers online, instead of requiring startup by a manufacturer’s representative. Adding factory-installed options like the variable frequency drive (VFD) pump package to control flow, K-12 school staff eliminate cost and complexity of expensive flow meters typically needed for commissioning.

Other factory-installed options such as the fan VFD control enhance part load efficiency, regardless of the chiller size. Modulating the condenser fan speed, rather than turning it on and off, enables a more stable and efficient operation. This control also reduces energy consumed by the fan motor, reducing energy costs and noise.

Simplified Maintenance

Thanks to today’s equipment design, controls and refrigerants, chiller efficiencies have improved and now operate with tighter operational tolerances. To ensure dependable and efficient operation, maintenance is critical, which can add pressure for facility managers who need to manage a broad set of systems across a school environment. Even more challenging is that training may not be a priority for many K-12 schools; yet the complexity of screw chiller systems requires outside support for ongoing maintenance.

Air-cooled scroll chillers are a different story. Some of the newer scroll chillers use a simple, robust and principled design for a trouble-free operation. With all-aluminum microchannel heat exchanger technology and proven compressor equipment, these scroll chillers require minimal maintenance. In-house staff can better maintain and obtain parts, it easier to ensure the system runs consistently. Many scroll chillers also use environmentally responsible R-410A refrigerant — which has no ozone depletion potential or phase-out schedule — and meet ASHRAE 90.1 2013 and FEMP 2012 standards. Schools gain the double benefit of minimizing a facility’s environmental footprint while lowering annual energy costs.

Service Consultants

K-12 schools can extend the benefits of choosing air-cooled scroll chillers with the expertise of service teams who can match a plan to the school’s budget levels and desire to sustain the HVAC investment. Facility consultants and technicians can customize and deliver upon plans for annual maintenance, help bridge staffing gaps, or assist with capital asset planning and HVAC system replacements and upgrades. The most qualified experts will respond swiftly and quickly, and easily navigate today’s highest energy efficient systems and proprietary HVAC technologies, like the newest designs in scroll chillers.

Eddie Rodriguez is a director of product planning at Daikin Applied. He has a mechanical engineering degree and has worked in the HVAC industry for 22 years.

Robert Landes is a product manager for screw and scroll products and has been with the Daikin Applied chiller group since 2008.

This article was originally published on School Construction News.